Welcome to SICHANGO VISION TECHNOLOGY

Web Inspection System for Print Quality Control: Discover SICHANGO Observer 4000, Scout 3, Ov100 200

In today's high-speed printing and converting industries, defect-free output isn't just a preference—it's a necessity. Whether you're printing flexible packaging, labels, or film materials, having a reliable Web Inspection System in place is the key to minimizing waste, reducing customer complaints, and maximizing productivity.

What Is a Web Inspection System?

A web inspection system is an advanced, video camera label inspection solution used to monitor and inspect materials moving through a production line at high speeds. These systems detect printing errors, surface defects, registration issues, and more—in real time. For printers and converters in industries like flexographic printing, pharmaceutical labeling, and flexible packaging, the right web inspection system can be the difference between profit and loss.

🌟 Featured Web Inspection Systems by SICHANGO

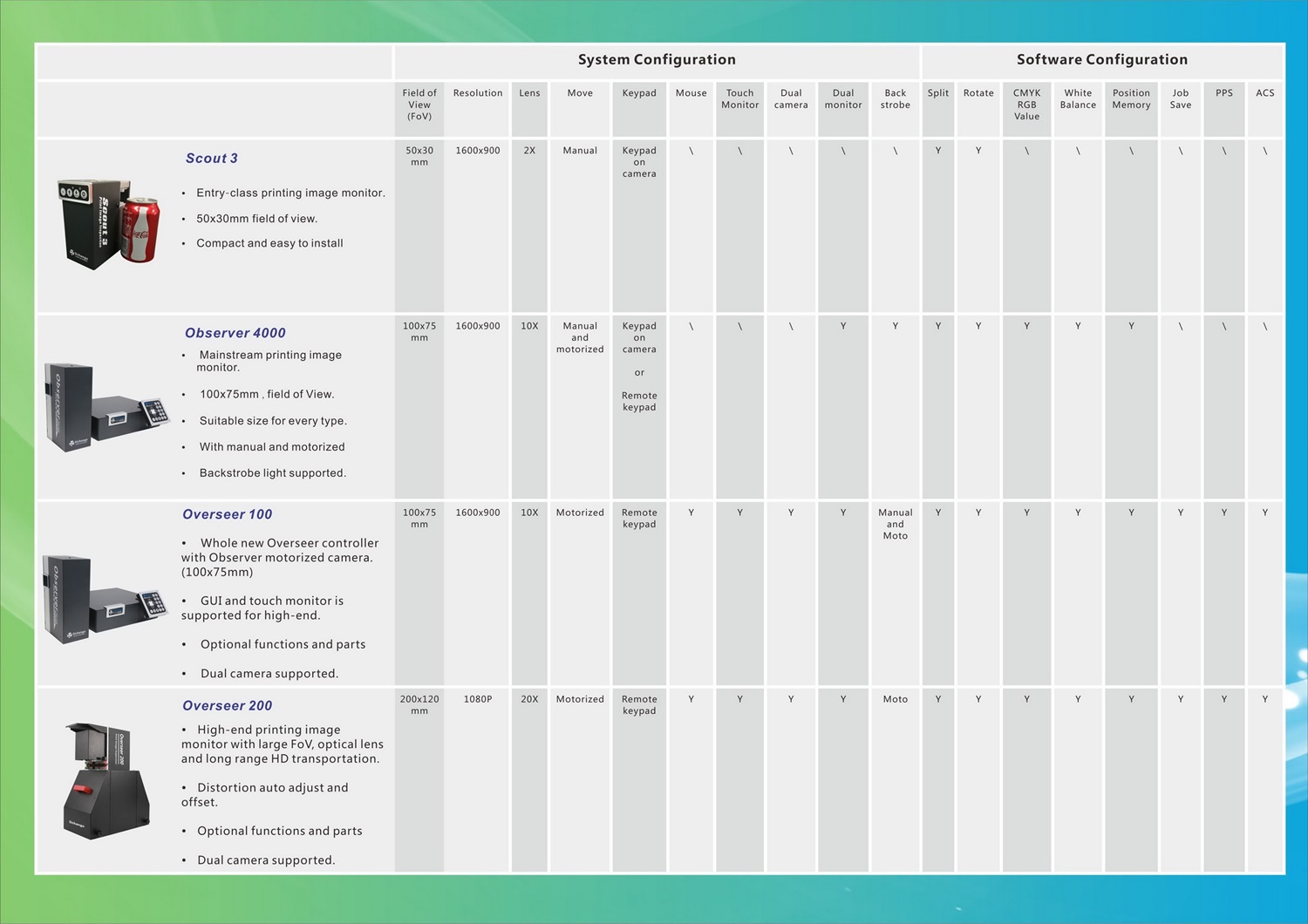

1. Observer 4000 – High-End Smart Vision System

The SICHANGO Observer 4000 is a top-tier video camera label inspection system designed for demanding applications in flexographic and gravure printing.

Key Features:

Ultra-HD color camera with high-speed frame capture

Real-time printing defect monitoring: misprints, registration errors, color drift

Advanced lighting and zoom functions for tiny label flaws

Seamless integration with various printing presses

Ideal for high-volume label and packaging printers

Best for: Premium packaging, security printing, and pharmaceutical labels

2. Scout 3 – Compact & Affordable Solution

If you’re looking for a cost-efficient inline inspection system, the Scout 3 delivers reliable performance in a smaller form factor.

Key Features:

Full-color inspection for label rolls and narrow webs

Touchscreen interface for easy setup and use

Detects missing print, color variation, smudges

Smart pattern matching algorithm for repeat print jobs

Best for: Label printers, startups, and budget-conscious converters

3. Overseer 100 – Fast & Flexible Web Inspection

The Overseer 100 offers powerful real-time printing defect monitoring at high speeds. Built for flexo and digital printers, it provides maximum reliability under demanding conditions.

Key Features:

High-resolution camera with LED lighting

Flexible zoom & tracking

Continuous monitoring of edge, print, and surface defects

Efficient in flexo printing defect detection

Best for: High-speed flexo printers, wide-web materials, converters

4. Overseer 200 – Smart Automation with AI Integration

For those needing advanced automation, the Overseer 200 is the intelligent choice. It combines AI-powered smart inspection for label printers with a robust camera platform for consistent, hands-free operation.

Key Features:

Automated defect classification and alarm triggering

Auto-learning mode to identify recurring issues

Integrated reporting system for traceability and compliance

Supports remote diagnostics and software updates

Best for: Pharmaceutical packaging, regulated markets, 24/7 operations

✅ Why Choose a Web Inspection System?

Implementing a web inspection system means you can:

Eliminate label printing errors before they reach customers

Improve overall quality control in label production

Reduce production downtime and material waste

Detect defects in real time, not post-production

Ensure consistency with inline label inspection camera technology

🎯 Applications Across Industries

SICHANGO web inspection systems are widely used in:

Label Printing – Ensure barcode, batch, and allergen text accuracy

Pharmaceutical Packaging – Comply with serialization and print integrity

Flexible Packaging – Detect streaks, wrinkles, and ink splatter

Cosmetic and Luxury Products – Maintain flawless high-end finishes

Food & Beverage – Confirm print readability and hygiene requirements

🛠️ Optional Features and Integrations

Dual-camera support

comparison for artwork verification

Defect marking systems

Integration with press control units

📈 Future-Proof Your Print Production

As printing technology evolves, so do the demands for 100% print quality assurance. SICHANGO’s web inspection systems — whether it’s the Observer 4000, Scout 3, Overseer 100, or Overseer 200 — are built to help you stay ahead of defects, not behind them.

📩 Ready to Upgrade Your Web Inspection?

Whether you need a compact solution like Scout 3 or a full-featured platform like Overseer 200, we have the right system for your needs.

Contact us today to request a demo, quote, or consultation on how to improve your web inspection workflow and eliminate printing defects once and for all.

Hot Selling Model Observer 4000M Web Inspection System